Safety Systems

Given our expertise in process, automation and combustion systems to the oil and gas, petrochemicals, chemical and pharmaceutical industries, safety systems are a priority in almost all projects handled by our team.

Safety systems are crucial for preventing accidents and protecting both people and equipment in various industrial and commercial settings, using components that are specifically safety rated to minimise risks and ensure compliance with stringent safety regulations.

At UNICAT Technologies, our teams of engineers are certified to relevant software standards for a wide range of industries and applications, enabling us to offer all aspects of management, design, integration and SIL verification of process safety systems.

- We Innovate

- We Design

- We Build

- We Install

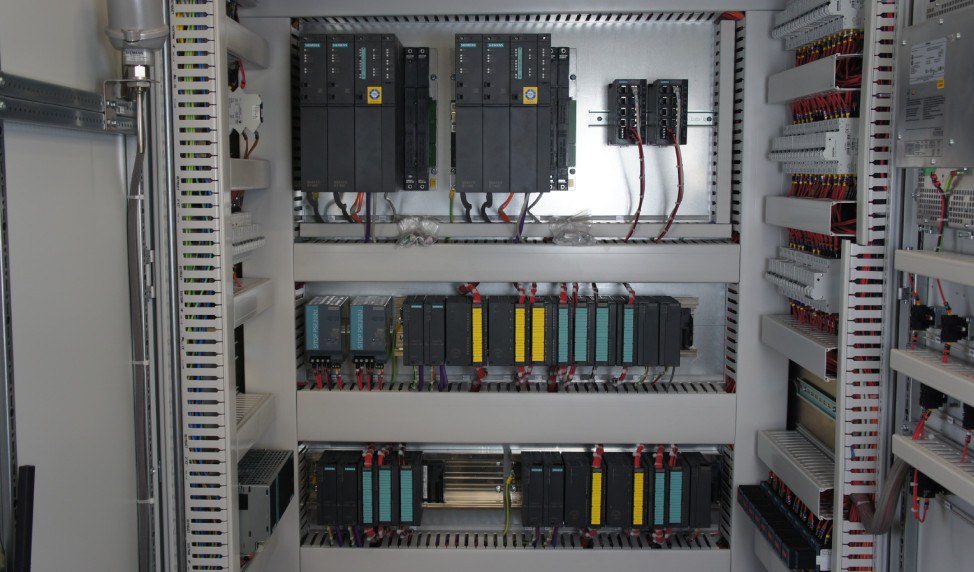

Integrating and verifying complex safety systems

We are experienced in designing, building and installing process control systems such as DCS, PLC and SCADA, as well as safety instrumented systems, such as ESD controllers.

Our TÜV and Siemens Safety Software certified Functional Safety engineers have a wealth of experience integrating and verifying complex safety systems.

We operate an integrated Functional Safety Management System for the implementation of functional safety standards BS EN 61508 and BS EN 61511 and provide expert resources for clients including dedicated services such as UL 508A and 698A certification, TUV certified Functional Safety and CompEx certified Design for Explosive Atmosphere.

Some common control panel safety systems and features include:

- Safety PLCs (Programmable Logic Controllers) - Designed with built-in safety features and redundancy to ensure reliable operation in critical applications.

- Voltage and Current Monitoring - Continuously measuring voltage and current levels, providing early warnings of potential issues or failures.

- Explosion-Proof enclosures - Control panels and electrical equipment used in hazardous locations are housed in explosion-proof enclosures, constructed to withstand internal explosions and prevent the release of sparks or flames into the surrounding atmosphere.

- Intrinsic Safety (IS) – Electrical circuits and devices designed to operate at low energy levels that are incapable of igniting flammable substances.

- Circuit Protection Devices – Including fuses, circuit breakers, and ground fault circuit interrupters (GFCIs) to protect against electrical overloads, short circuits, and ground faults.

- Purging and Pressurization Systems - Used to create and maintain a safe environment within enclosures by purging potentially hazardous gases or dust and pressurising the enclosure with clean air or inert gas.

- Safety Alarms and Indicators - Visual or audible alarms which alert operators to potential hazards or abnormal conditions, such as high temperatures or pressure.

- Emergency Stop (E-Stop) Buttons - Large, prominently placed buttons to allow operators to quickly shut down machinery or processes in case of an emergency.