Hazardous Area / ATEX rated panels

Explosion-proof panels to meet worldwide standards

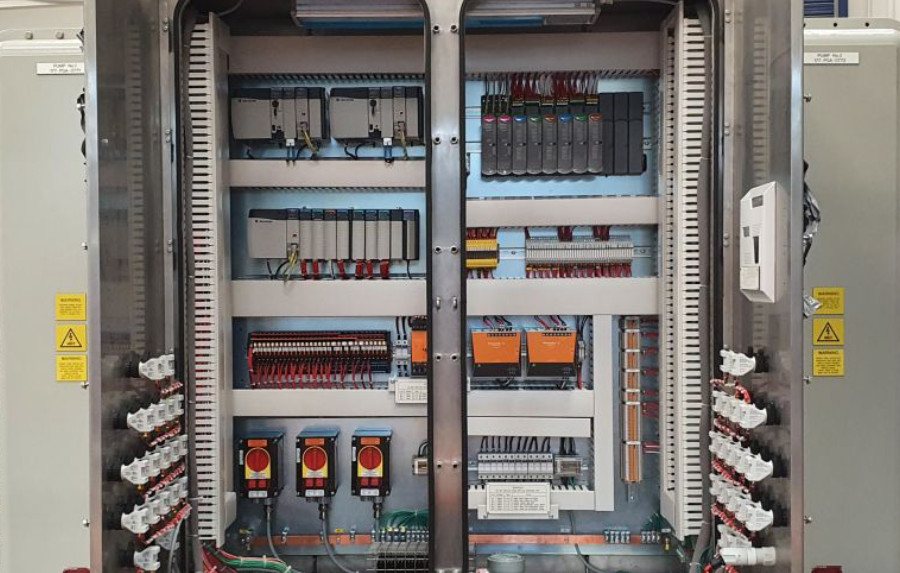

At UNICAT Technologies we have extensive experience in the design, manufacture and supply of Hazardous area (HazLoc) control panels, terminal boxes and push-button stations to meet demanding European (ATEX) and North American standards for use in potentially explosive atmospheres.

- We Innovate

- We Design

- We Build

- We Install

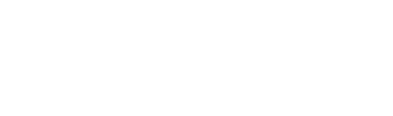

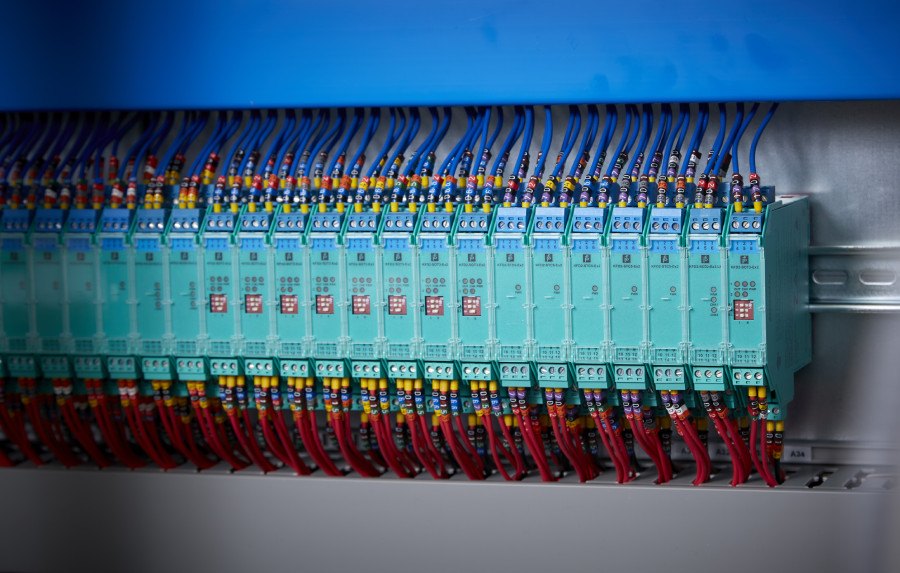

Stainless Steel Explosion-Proof Control Panels for Hazardous Environments

Stainless steel, explosion-proof control panels are designed and built with sealed enclosures to prevent the entry of flammable substances and to protect internal components, with cooling systems used to reduce the risk of overheating and potential ignition.

Such systems are required in industries such as oil and gas, petrochemicals, pharmaceuticals, mining, and other sectors where flammable substances are handled.

Meeting European ATEX standards

ATEX European Union directives outline the safety requirements for equipment and protective systems used in potentially explosive atmospheres where explosive gases, vapors, or dust may be present.

At UNICAT Technologies we have extensive experience of designing and building appropriate equipment to meet specific classification zone requirements which ATEX-rated control panels are used in.

Classified zones we supply for include:

ATEX zones for gases/vapour:

- Zone 0 (gases/vapours) - An area in which an explosive mixture is continuously present or present for long periods.

- Zone 1 (gases/vapours) - An area in which an explosive mixture is likely to occur in normal operation.

- Zone 2 (gases/vapours) - An area in which an explosive mixture is not likely to occur in normal operation and if it occurs it will exist only for a short time.

ATEX zones for dust:

- Zone 20 (dusts) - An area in which an explosive mixture is continuously present or present for long periods.

- Zone 21 (dusts) - An area in which an explosive mixture is likely to occur in normal operation.

- Zone 22 (dusts) - An area in which an explosive mixture is not likely to occur in normal operation and if it occurs it will exist only for a short time

Meeting North America and Canada Standards

In North America and Canada, hazardous locations are set into classes, divisions and zones based on the type of explosive atmosphere that may be present, and our team at UNICAT Technologies is highly-experienced in working to, and meeting these standard requirements.

The classes are;

- Class I – A location made hazardous by the presence of flammable gases or vapours that may be present in the air in quantities sufficient to produce an explosive or ignitable mixture

- Class II – A location made hazardous by the presence of combustible or electrically conductive dust

- Class III – A location made hazardous by the presence of easily ignitable fibres or flyings in the air, but not likely to be in suspension in quantities sufficient to produce ignitable mixtures

The divisions are;

- Division 1 – A location where a classified hazard exists or is likely to exist under normal conditions

- Division 2 – A location where a classified hazard does not normally exist but is possible to appear under abnormal conditions

The zones are;

- Zone 0 – An area in which an explosive gas atmosphere is continuously present for a long period of time

- Zone 1 – An area in which an explosive atmosphere is likely to occur in normal operation

- Zone 2 – An area in which an explosive gas atmosphere does not normally exist

Accreditations, Competencies and Partnerships

TUV Certified Engineers

UL698A – Industrial Control Panels Relating to Hazardous Locations, including intrinsically safe circuits