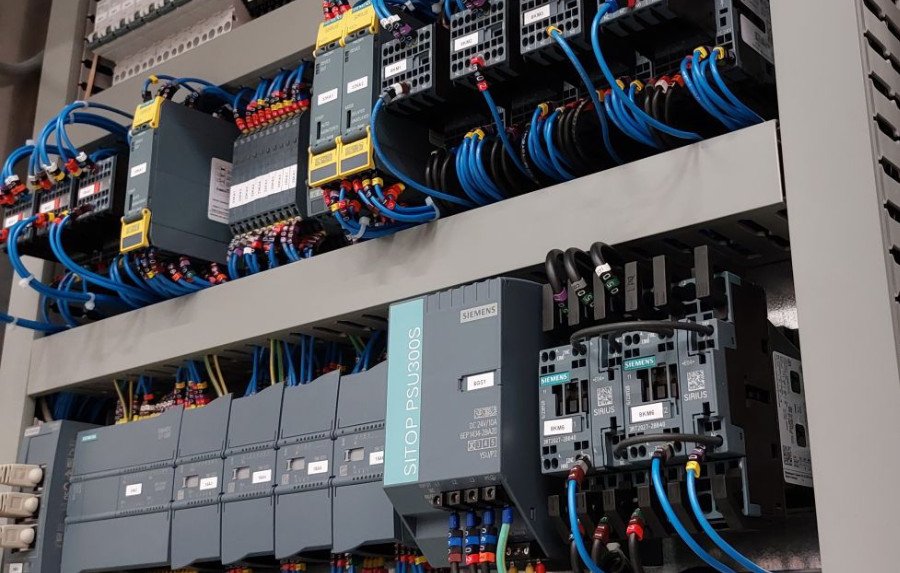

Control Panels

Specialists in control panels

From simple floor-standing and wall-mounted one-off systems to some of the most complex Control Panel system in industry, our team at UNICAT Technologies has extensive experience of designing, manufacturing and installing systems.

We can design, manufacture and install control panels in various shapes, sizes and arrangements to fit your requirements, crucially providing the best performance in challenging environments.

- We Innovate

- We Design

- We Build

- We Install

International, on and offshore expertise

We work across the oil & gas, industrial gases, chemical, pharmaceutical, renewables and engineering industries, designing, manufacturing and installing control panels tailored to our customers’ requirements for use in many countries, both on and offshore.

We are specialists in Hazardous area (HazLoc) and SIL rated control panels worlwide, and also supply Environmental Control Systems with both Heating and Vortex Air Driven Cooling Systems for use in extreme temperatures.

Benefits to your business

A truly bespoke Control Panel can play a critical role in ensuring reliable and sustainable processes and production, ensuring increased operational efficiency, enhanced safety and complete compliance.

Accreditations, Competencies and Partnerships

Siemens Solution Provider (Partner status for SIMATIC Automation System, SIMATIC HMI Human Machine Interface, SIMATIC NET Industrial Communication)

UL508A/UL698A – Industrial Control Panels Relating to Hazardous Locations, including intrinsically safe circuits

Rockwell RCSI

TUV Certified Functional Safety engineers

For further information, or to discuss the Control Panel requirements of your business, contact our team today on 01484 550390

Related Project - Gas Mixing Station

Client Major UK stainless steel manufacturer

Services

- Gas control skid

- Combustion Design, Manufacture

- Project Management

- Installation & Commissioning

- Control Panels

Scope of project

The client wanted to adopt a new steel making process on their 130 tonnes electric arc furnace to improve safety and productivity. The aim was to eliminate the personnel and plant dangers and yield losses associated with boil-over in the EAF or AOD transfer ladle.

This improvement was to be…